Showcase

Fluid adapter

The following showcase is about a specific fluid adapter, used for the collection and disposal of various chemical fluids, used in the analysis process of beet sugar analysis. The part is designed for a new generation of beet sugar analyzers.

The original part, as displayed below, was designed for traditional fabrication methods, like machining and welding. The design target of this particular optimization was the reduction of the total number of parts.

The new part that was designed and optimized, consists of just one single part, designed to be printed in AISI 316 stainless steel.

Comparison

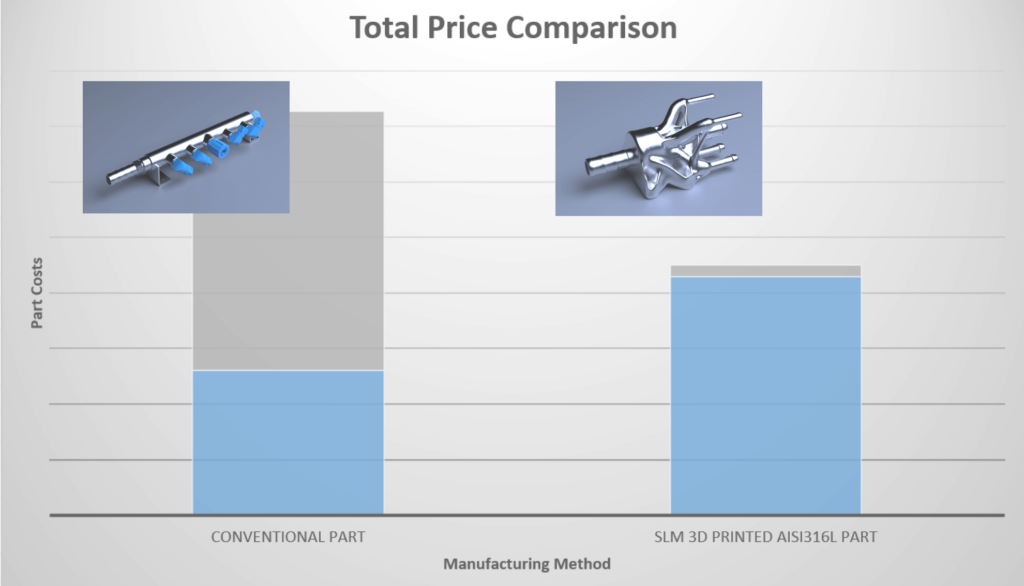

The total price comparison between the conventional produced part, (on the left) and the optimized SLM printed (AISI 316) part, (on the right) is displayed below. The total costs for the optimized, printed part turned out to be 38% lower than the conventional produced part.

The blue regions in the graph represent the material costs. As clearly visible, the conventional manufactured part is in terms of material costs, cheaper than the printed part.

The grey regions in the graph represent the total costs as a result of working hours (rated as: low, internal, hourly costs) spend on the fabrication of the part. This includes, sourcing parts, ordering parts, booking parts on inventory, picking the parts from inventory for assembly, welding the parts, cleaning the parts, and final assembly of the parts.

The final conclusion of the comparison is that the optimized and printed part is 38% more cost efficient than the conventional produced part.