Showcase

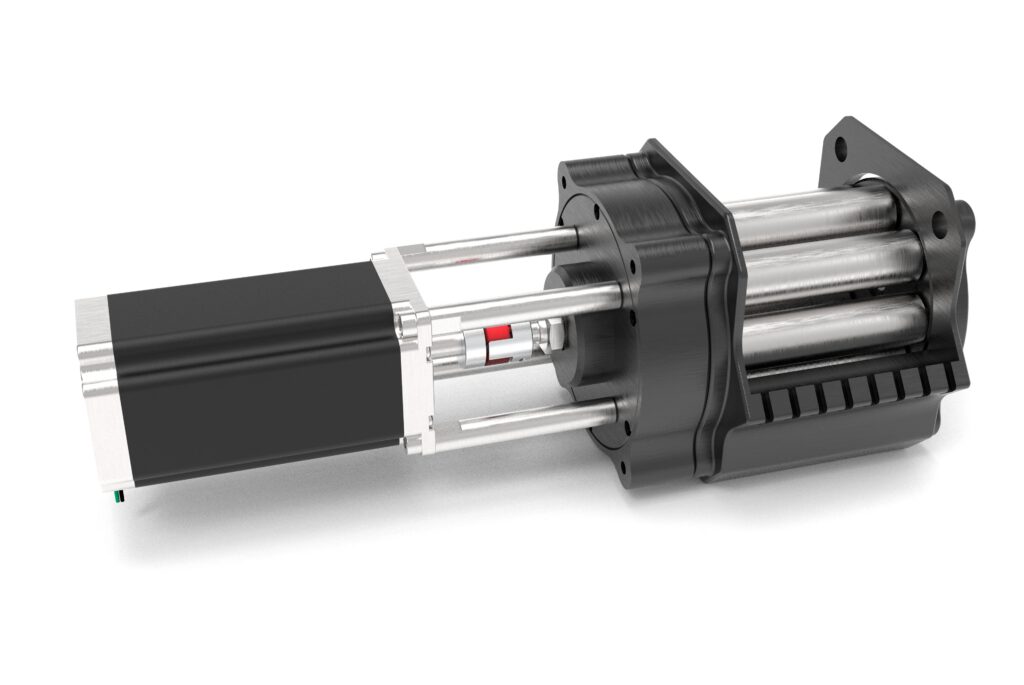

Peristaltic Pump, stepper motor bracket

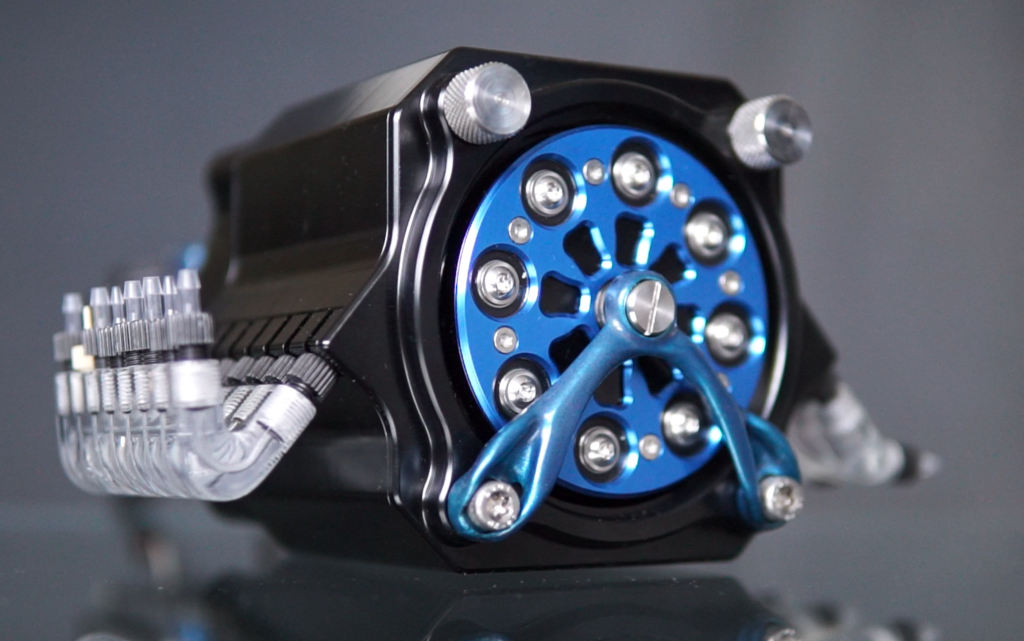

This ultra precise, peristaltic pump has been developed for use in a specific chemical analysis device for the beet sugar industry, a so-called Analyser. For this purpose, the pump needs to have an highly precise repeatability. Because of this, it is equipped with a stepper-motor for precise motion control of the main rotor drum.

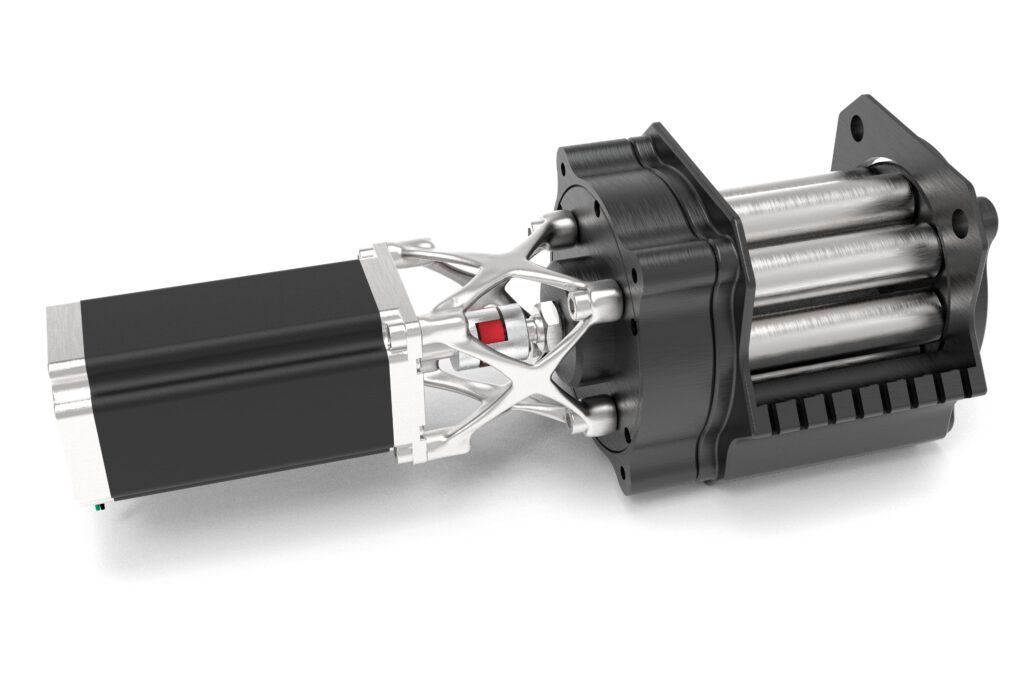

In the old situation the motor was mounted with 4 stainless steel rods. The mounting rods were all CNC machined .

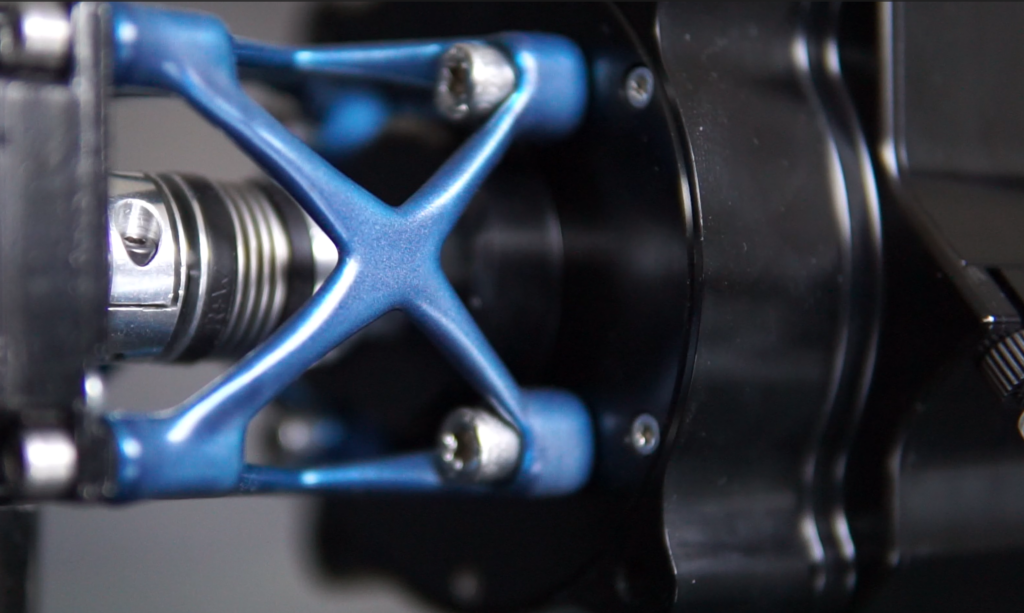

In the new situation, the optimized single part, replaces all 4 rods. Like the rods, the new, optimized bracket is also designed for stainless steel. The printproces of choice for this part is SLM printing.

For the new bracket a weight reduction of 19% was realized, compared to the old situation. The manufacturing costs dropped by 57%, comared to the old situation.

The new optimized bracket consists of one single part, printed with SLM print technique, in stainless steel.

Weight reduction: 19%

Manufacturing cost reduction 57%

Old situation, consisting of 4 CNC machined, stainless steel rods.

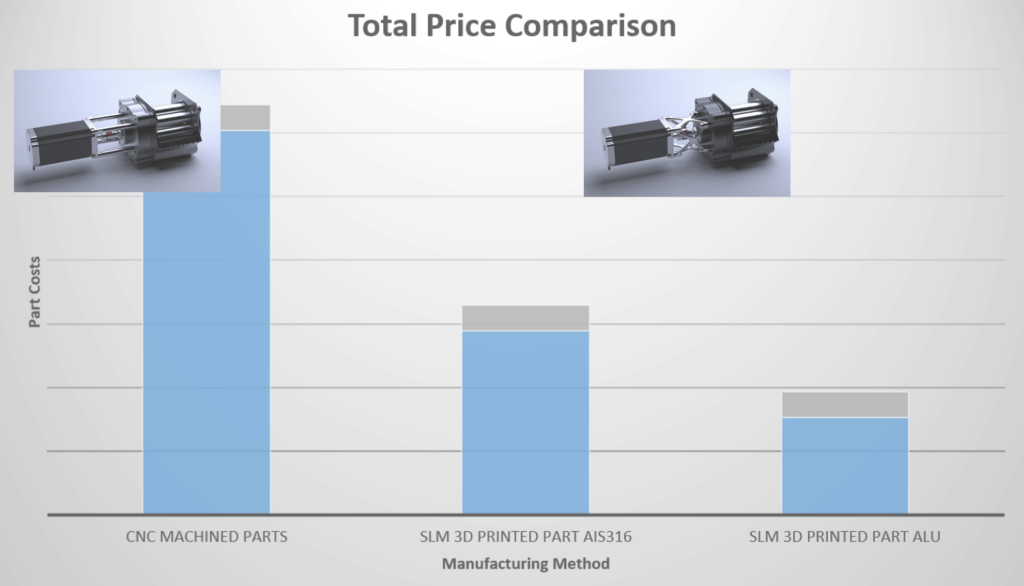

In the overview below, the total price comparison is displayed. Blue represents the material price, grey represents the handling costs.

On the left, the conventional fabrication method is displayed, in the middel the SLM printed part in AISI 316, on the right SLM printed part in Aluminium