Why mechanical design efficiency is so important

"The absence of certain components during the final assembly of a machine is a nightmare for any machine builder. Yet, this happens more often than we would like."

Designing a machine accounts for only a portion of the total machine costs. Every component must ultimately be guided through an entire organization before it actually reaches the final assembly of the respective machine. This includes purchasing, booking in, storing in inventory, selecting for assembly, booking out, gathering for final assembly, and, of course, the final assembly itself. The more components there are, the higher the costs and the greater the chance of errors in the entire work preparation process. And we all know what a forgotten component means… work interruptions, frustration, and unnecessary expenses.

The hidden benefits of fewer parts in your machine design

"Every extra bolt is an extra risk."

Components that cannot be assembled during the final assembly of a machine pose a risk for any machine builder. In the best-case scenario, the correct component can still be arranged, often requiring urgent orders from suppliers, resulting in high costs. In the worst-case scenario, the entire assembly of the machine comes to a standstill—a nightmare for any machine builder, unfortunately, a familiar one.

The causes can be very diverse: incorrect specifications, errors in drawings, incorrect orders, incorrect deliveries, improper entry into the system, supplier errors, miscommunication, out-of-stock items, limited availability, and so on. Almost always, it comes down to human errors, which is quite understandable, as people are simply not perfect.

Some companies believe the solution to these problems lies in better and smarter ERP software. While this can mitigate some errors, incorrect entries in such a system will inevitably lead to incorrect outputs. In my view, it makes more sense to start with the machine design itself, actively reducing the number of components as much as possible during the design process.

"Because fewer components mean fewer chances of errors during final assembly, as well as lower costs throughout the entire work preparation process."

How design efficiency works

"If every component represents an order, a check, an inventory position, and a risk of errors—why do we continue to use so many?

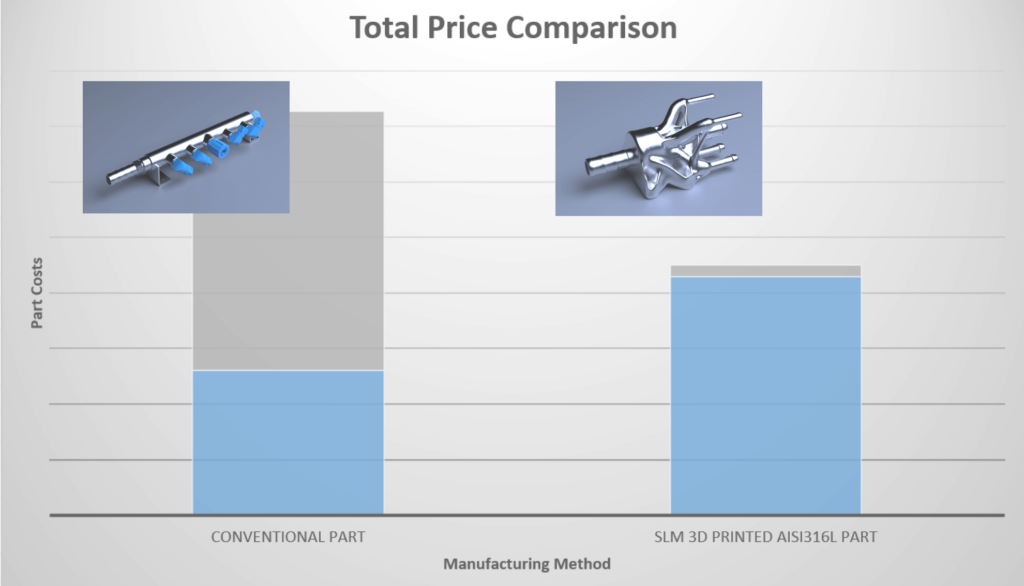

Efficient design, with fewer components, is the key principle. This is achievable with the latest technologies, such as ‘Topology Optimization’ combined with ‘Additive Manufacturing’. The combination of these two techniques can often lead to cost savings. This new approach to design follows three steps. In the first step, design limitations resulting from conventional processing techniques, such as CNC machining, welding, and sheet metal work, are eliminated. Next, components that can be merged into a single part are identified. In the final step, the new part is optimized for the 3D printing process by reducing its weight as much as possible and to achieve the most optimal shape. Specialized software is used for this process, that will calculate the most efficient form for the new component based on various load conditions.

The final component that is created is often not only lighter than the parts it replaces, but in many cases, it is also more cost-efficient. Additionally, internal hours are saved, as fewer components need to pass through the work preparation process. This also contributes to reducing the risk of errors during this process.

Other benefits

"Are there any other benefits that come with 'Design for Additive manufacturing'?"

Another additional advantage is that the average CO₂ footprint is lower for components manufactured using Additive Manufacturing.

Finally, there is the forecast for the average cost price of Additive Manufacturing. While the development of conventional processes has reached its endpoint, the advancement in the Additive Manufacturing industry is still in full swing. Over the past 20 years, the average cost estimate of a 3D SLM-printed component has dropped from 4000 euros to 400 euros. In the next 5 to 10 years, a further halving is expected for almost all 3D printing processes. This means that 3D-printed components will only become more cost-effective in the coming years.

Discover our services